Well known as experts in the inspection, cleaning, and maintenance of treated water storage assets such as service reservoirs and contact tanks we are expanding our offering in the field of specialist pipeline services with two new services.

We are now able to offer two products unique in the UK & Irish market, the first allows pipeline condition to be assessed while remaining “in service”, and the second provides surface cleaning and preparation ahead of re-lining works.

Partnerships are now in place with to provide the Tomahawk system from Canadian firm Envirologics Engineering Inc, and the MTA Pipe Inspector technology from Austrian firm MTA Messtechnik GmbH. Discussions are ongoing for identifying pilot projects with water companies and their supply chain.

Jim Panton, our CEO explains the strategy behind the new deals, “As an extension of our service reservoir focused operations we are increasingly supporting the commissioning and testing of new tanks and new pipelines for our clients and partners.”

“This has developed now to the provision of cleaning, flushing, and decontamination works to existing distribution systems. If you add to this our ability to provide in-tank treatment systems, including mixers and THM reduction solutions through our partnership with PAX Water Technologies in California, we can truly support our clients in their mission of providing the best quality water from treatment works to tap.”

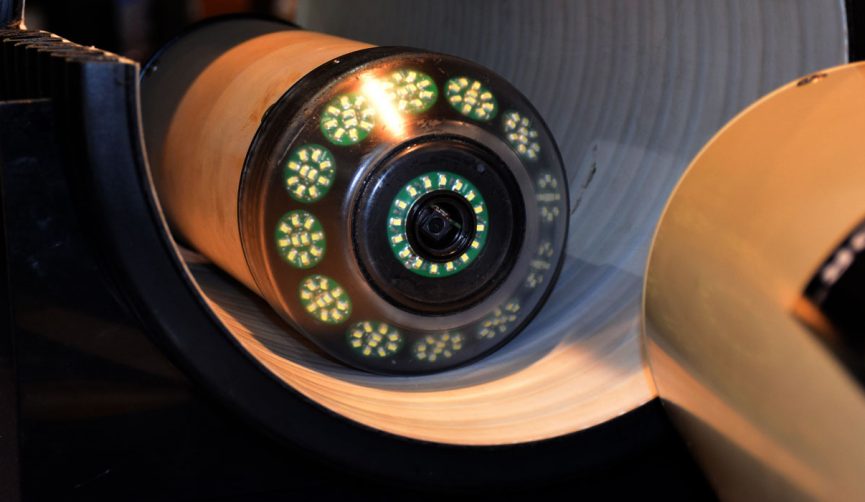

MTA Pipe Inspector is an autonomous leak detection and inspection device that can be deployed into live mains whether they are potable water, waste, hydro or industrial. Once deployed the equipment follows the flow taking HD optical and acoustic readings from a cable-less platform.

The equipment is suitable for pipe diameters from 100mm up to 3000mm and can complete sections up to 20km with a single deployment.

Once completed the data is uploaded and assessed by the team at MTA, we are then able to work with our clients to prioritise their investment preventing leakage, turbidity and reducing the frequency of bursts.

Features

- Optical examination

- Sound recording for detection of smallest leakages with pinpoint accuracy down to 10l/h at 5 bar operating pressure

- Pressure recording along the entire pipe length

- Turbidity measurement (optional)

- Conductivity measurement (optional)

- Temperature measurement

- Length measurement including meter display

- Video in HD-quality

For more information, contact the team on 01896 663 330 or email info@pantonmcleod.co.uk

Keep up to date with all our latest news via Twitter. Follow us at Panton McLeod