Gravity Filter Bed Cleaning In Situ

Replacing media and fittings in Rapid Gravity Filters is carbon intensive, costly and time consuming. Our In-situ innovative cleaning method improves filter performance while saving time, money and the environment.

Optimising RGF Performance Through Regular Cleaning

Are your Rapid Gravity Filters (RGFs) losing efficiency, driving up costs, or requiring frequent maintenance?

The PM cleaning system is a proven solution that restores filter performance, extends filter life by up to 2.5 years, and reduces operational costs. Backed by over a decade of research and successful application across 30+ filters, our PM77 cleaning system is a game-changer for water utilities looking to optimise their filtration systems.

Investing in routine maintenance today means saving big tomorrow!

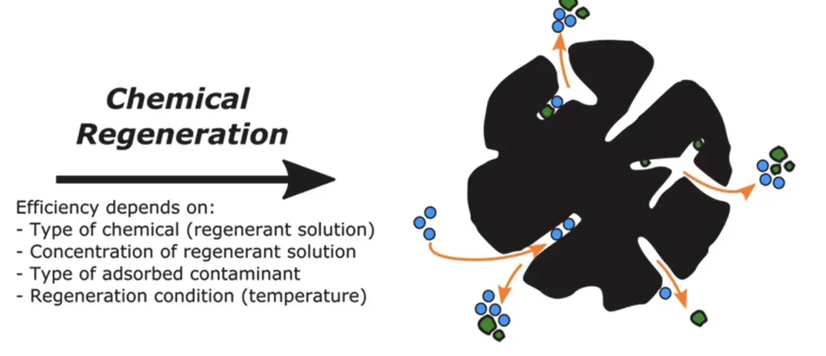

Iron & Manganese bio-fouling reduces the performance of gravity filter beds causing blocked filter floors & nozzles which reduces backwash and air scour performance. By utilising our PM Solution in the cleaning of Gravity Filter Beds we can keeps your operations running smoothly.

Don't let blockages stand in your way!

FITTINGS AND MEDIA

The build up of biofouling in the very narrow flow through channels of your filter nozzles or mesh floors will reduce flow in both directions. This will then lead to reduced filter performance and media issues due to the reducing backwash capability. Biofouling can also accumulate on the media itself which gradually increases the size of media particles and causes further performance reductions.

Removing this build-up, in-situ, with a PM chemical rehabilitation can improve filter performance dramatically.

PERFORMANCE

High backwash and air scouring efficiency is key to maintaining filter bed performance. Once the restricted flow components, designed to let fluid through but hold back solids, have been released from the blockages that biofouling creates over time, your filter bed will operate more efficiently again.

You no longer need to replace the components or media to achieve this. In the same way, you would not replace shower components in your bathroom when the flow rate out through the plug reduces.

METHOD

Our method sticks to a low pressure and low risk approach which causes minimal operational disruption. Every application is unique and depends on the type of filter bed and treatment plant setup.

In partnership with our clients we develop a bespoke method for each project. We have developed a variety of adaptations now for a range of different filter styles. We make sure we always target the critical problem areas of each filter bed, minimising the chemical required and the waste removal.

HEAR FROM A CLIENT

Scottish Water were having issues with nozzle blockages causing flow rate, head-loss and backwash pressure challenges on their filter beds. Rather than replace the media, as might have been done before, they trialled the innovative Panton McLeod RGF rehabilitation option - with great results across all the beds in that treatment plant.

Scottish Water are now regular users of this method on other treatment plants.

MAILING LIST SUBSCRIPTION

Join our mailing list for important industry updates and news. We’ll never sell or share your email address, and you can unsubscribe at any time.