Industrial Water Projects

Panton McLeod now has over 15 years of experience working in industrial based projects such as in the Power, Chemical Production and Oil and Gas sectors.

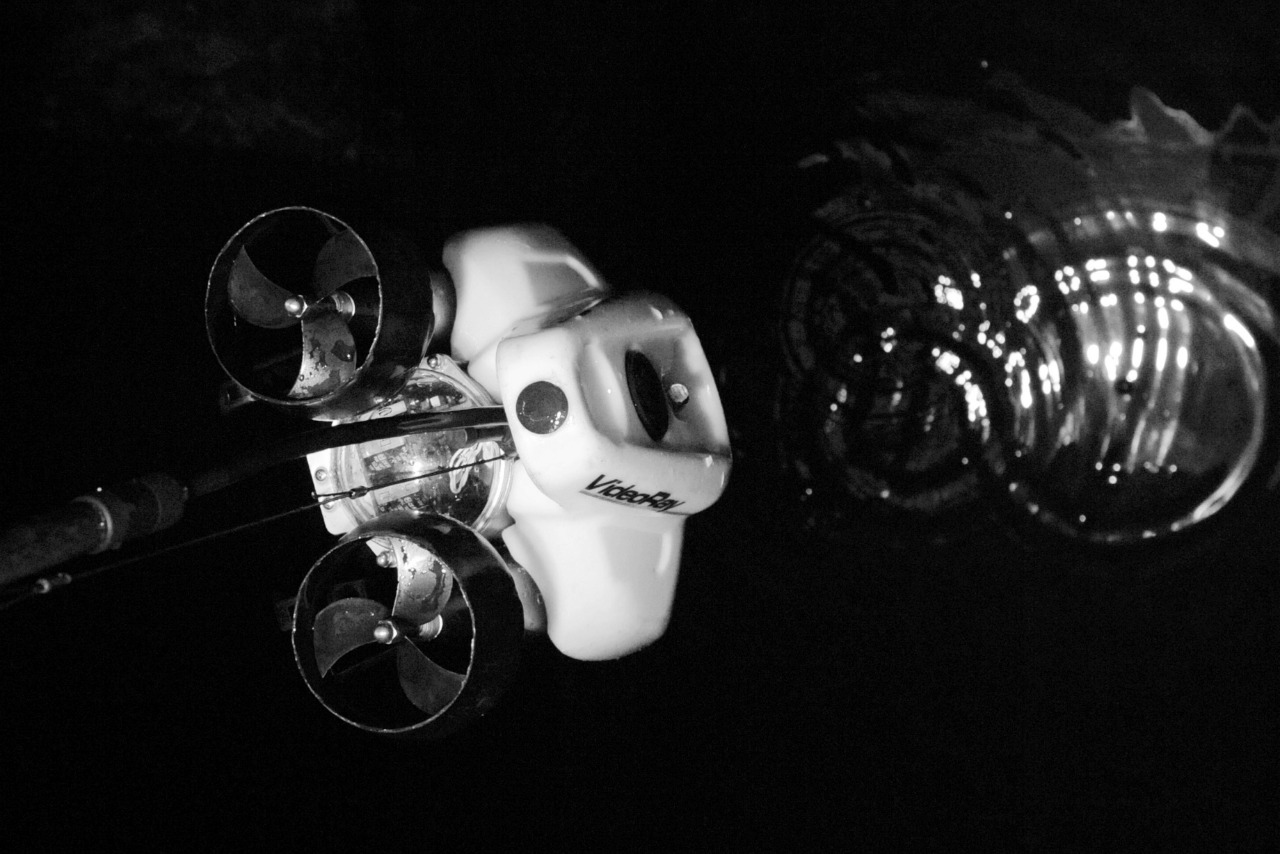

While the majority of this work involves our underwater ROV inspection and cleaning systems - preventing huge time loss and costs associated with shutting systems down for this otherwise quick maintenance - we have also carried out confined space inspections and tank cleaning activities.

Ineos Runcorn

Ineos operations at their Runcorn site are of strategic national importance to the UK and focus mainly on the production of chlorine, caustic soda and chlorinated derivatives. INOVYN also produces sulphur chemicals and salt at the Runcorn site, which has one of the largest membrane electrolysis units in Europe.

With initial projects in 2007, Panton McLeod has completed numerous projects at Runcorn with the latest taking place in 2019. This includes numerous cooling tower sumps, a high grade and high temp water storage vessel and outdoor open water concrete storage reservoirs.

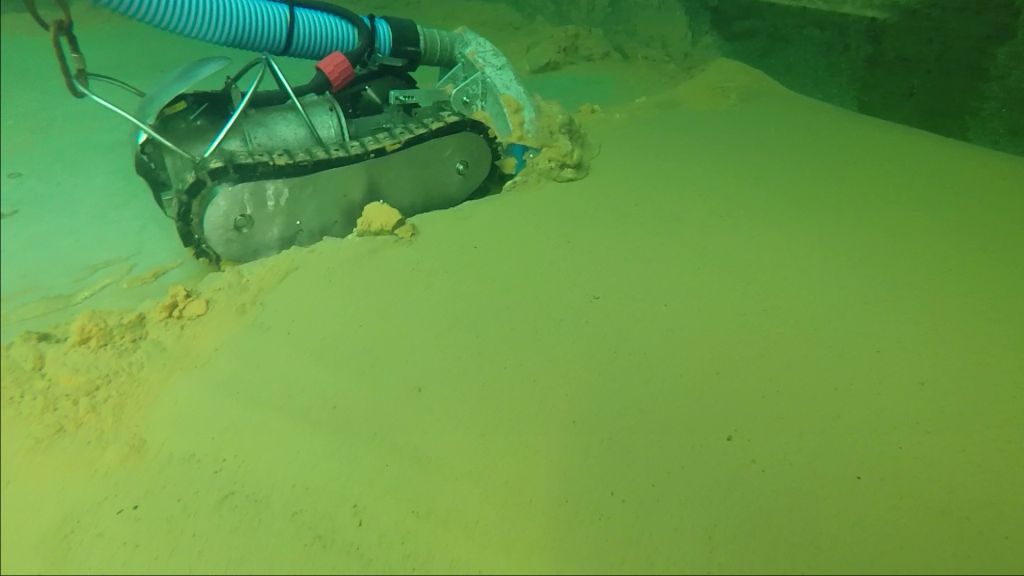

Oil Refinery Fire Water Tanks

The Valero Pembroke Refinery opened in 1964 and is one of the largest, most complex, refineries in Western Europe.

In 2015, Panton McLeod carried out an underwater survey and then the robotic removal of sediment from critical fire suppression water tanks to help maintain water hygiene requirements.

Doing this work with the system remaining online removed the site wide shut down complications and costs associated with not having that emergency water available during an off-line clean.

Combined Heat & Power Plant

Chemical Production Plant

In 2021, Panton McLeod carried out an underwater inspection of a cooling tower sump at a large industrial chemical production plant in the South of England.

This was then followed up with a robotic clean of the debris identified later in the year.

This short clip shows some of the observations from the inspection.

Power Station Process Tanks

Working with Environmental Risk Reduction Consultancy firm, Adler & Allen, in 2014, Panton McLeod carried out the first online cleans seen at a critical asset at one of the UK's key power stations without the the need for a plant shutdown.

The project objective at West Burton Power Station was to remove sediment and organic matter from the base of one of the plant's largest process tanks.

MAILING LIST SUBSCRIPTION

Join our mailing list for important industry updates and news. We’ll never sell or share your email address, and you can unsubscribe at any time.