One of the most widely known myths that people believed was that us humans only use around ten percent of our brains; with the rest being an underutilised area of grey matter.

Of course, after proper research carried out by experts, it turns out that nature would never allow such a colossal waste of resources.

However, the same cannot be said for everything that humans have designed and as we continuously revaluate systems and processes, we find ways of becoming ever more effective and efficient. What’s this got to do with the water industry you may well be asking?

Well, leveraging more value and capability from existing assets is a goal for any water utility; enhancing services for the same cost will please the customer and therefore the regulator, as well as the utility. In many cases, it is also more sustainable, making it a win, win, win. So, is the water industry missing a huge opportunity by ignoring service reservoirs (SRVs) and water storage assets? Are they our 90 percent of wasted grey matter?

Where is the opportunity and what is the current situation?

Treatment assets are often managed separately from networks, with separate priorities and objectives. For decades, utilities have focussed on bringing cutting-edge technologies to treatment plants to improve system water quality.

In contrast, investment in networks has focussed on pressure management, calm networks and leakage reduction. While this make sense, it doesn’t have to be binary. Certain assets can be managed to support both sets of objectives. For example; having achieved excellent water quality at the treatment works, it makes sense to manage and maintain that through distribution, ensuring it arrives at the customer’s tap in the same excellent condition.

However, apart from some reactive secondary dosing, water utilities generally do little to manage water quality through distribution. This is a risk but also a missed opportunity which can be addressed by leveraging more value from the hundreds of SRVs and water storage assets across the UK.

Low-cost optimisation of storage assets can maintain water quality

In the UK, SRVs and storage tanks are designed to meet the storage and hydraulic requirements of networks. This is reinforced by best practise textbooks like ‘Water Supply’, which claims that SRVs have four functions:

- To balance the fluctuating demand from the distribution system, permitting the source to give a steady or differently phased output.

- To give a suitable pressure for the distribution system and reduce pressure fluctuations therein.

- To provide a supply during a failure or shutdown of treatment plant, pumps or trunk main leading to the reservoir.

- To provide a reserve of water to meet fire and other emergency demands.

This engenders the underutilisation of many assets. Low-cost optimisation of tanks could enable them to fulfil the above roles and promote water quality; in effect becoming low-cost, decentralised, treatment assets operating closer to the customer and reducing the burden and capital expenditure requirements on distant treatment works.

Making water quality interventions in storage tanks and SRVs is already done worldwide and can be readily adopted by UK water utilities today. For example, efficient mixing of tanks is commonplace in the US and Australia. Mixing tanks results in a range of benefits that could mean:

- Fewer bacti failures

- Reduced taste and odour complaints

- Less frequent tank cleans

- Less interruptions to supply

- Better management of nitrification in chloraminated systems

- And even reduced chemical usage

How does mixing provide so many water quality benefits?

Large bodies of still water present several water quality risks including water ageing and dead-spots which can cause stagnation and bacterial growth. Standing water can also support the growth of biofilm on tank surfaces and sedimentation on floors. SRVs and tanks can be affected by chemical stratification with different concentrations of disinfectant at different tank levels. It all depends on tank cycling regimes, tank design, inlet and outlet position.

Mixing overcomes these issues by producing a homogenous body of water which improves water quality in several ways:

- Improved disinfectant blend time, making disinfection more efficient

- Eliminating chemical stratification

- Removing dead-spots and creating a uniform water age and quality in the tank. Results in:

- Calmer and more predictable networks

- Lower numbers of bacti failures

- Fewer taste and odour complaints that are a result of fluctuations in disinfectant level

- Reduced amounts of disinfection by-products (DBPs), such as Trihalomethane’s (THMs)

- Reduced build-up of sediments and biofilm increasing time required between cleans.

Technology from the US is now available in the UK and is proven to deliver the above while remaining acceptable to OPEX budgets thanks to patented energy efficient designs based on biomimicry.

Furthermore, mixing is a no-chemical solution that is easy to install and requires minimal maintenance.

Beyond mixing; treatment for specific water quality issues

While tanks can benefit from mixing it can’t address certain every issue. However, it is a foundational technology that can be built on to reduce THM levels and even proactively manage disinfectant residuals in distribution in near real-time.

Automatic disinfectant residual control

Disinfectants are used in potable water networks to manage water quality from treatment works to customers. Distribution system water quality is a delicate balance of regulatory compliance and customer satisfaction; operators must deliver adequate disinfectant residual while reducing the potential for DBP formation.

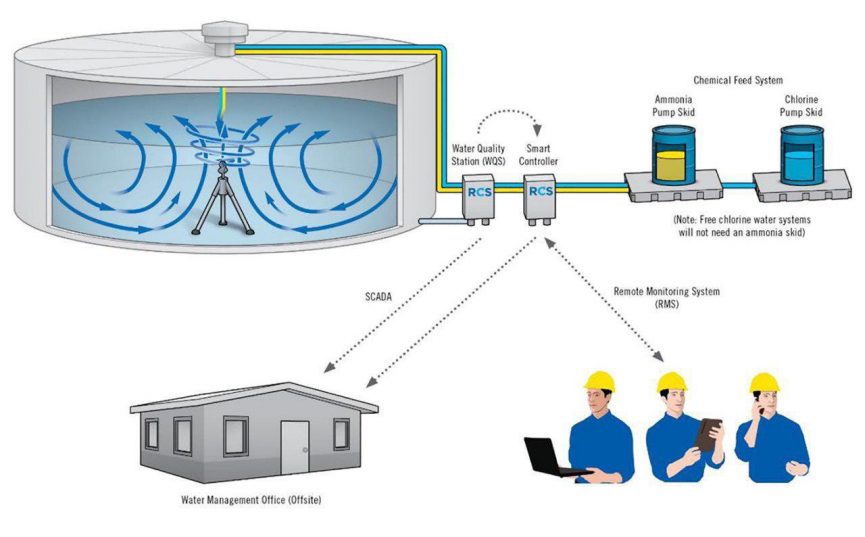

Sampling of mixed tanks provides a representative sample and real disinfectant levels; chemical disinfectant need only be introduced if this level is too low. Tank disinfectant residual levels can be automatically managed in real-time by integrating existing discrete functions: Mixing to achieve complete disinfection and chemical homogenisation, active monitoring to respond to changing tank conditions in real-time and instruct pumps to dose until the required set-point is achieved.

Destroying the myth and becoming as effective and efficient as nature

It is clear that SRVs are underutilised assets that can be optimised to be more effective and efficient while improving water quality. Tanks present an opportunity to mitigate water quality issues in networks and top up water quality efforts from treatment before reaching customer taps.

Mixing is the first step towards a calm, homogeneous, body of water which will reduce taste and odour complaints, bacti failures and interruptions to supply as well as providing a way to manage nitrification in chloraminated systems.

Furthermore, mixing can be enhanced with ventilation (and aeration) to reduce DBPs such as THMs or with an automatic sampler and dosing rig to automatically manage tank disinfectant levels in real-time.