Can improved forewarning help drive up efficiencies, prevent failures, and improve the quality of output for clients while also smoothing the resource profile for contractors?

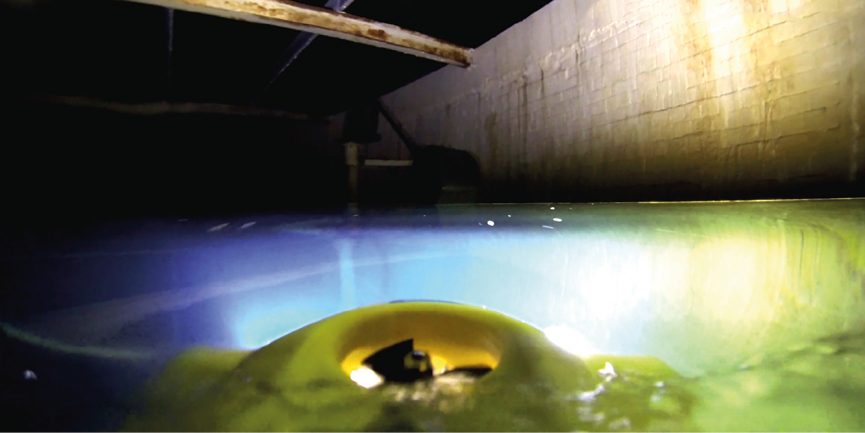

We believe that early investment in a wide programme of ‘live’ inspections using a dedicated potable water ROV (remotely operated vehicle) complete with a flood test would alleviate most of the issues faced by the industry year on year.

With one month gone in the new financial year and the traditional summer slow down inevitable for the Water industry (even if the appearance of summer is not) it is critical that Water Companies direct their resource to the most needy assets.

Inadequate knowledge of the asset base can lead to poor prioritisation and risk exposure to coliform failures especially over the summer when higher temperatures can see a spike in water quality issues.

Traditionally there is a large variation in workload over the 12 month period; clients would often like to tackle what they believe are the most critical projects early in the financial year.

Uncertain scope prior to removing the asset from supply increases the risk that a project commencing in Spring may overrun, thus preventing the asset being returned to supply before expected high demand in early Summer. This doubt and associated risk often result in projects failing to be signed off and therefore the opportunity is missed.

A second batch is therefore taken on during early Autumn but this has the disadvantage that the Christmas holiday season acts as a ‘hard stop’ for larger projects.

There is then a final push around mid-January which is delivered through to the budget year end in March.

Projects also take clients by surprise late in the year. For example, a roof flood test failure can quite often cause issues as budgets may already be stretched or, even worse, be totally depleted.

In addition to adding uncertainty to financial planning, this reactive approach can also lead to external repairs such as membrane installations being taken on during the cold and damp months of February and March. If better visibility was available these could be planned during the drier months when contractors often have a surplus of staff.

So how can robotic inspection using ROV’s help both parties? What benefits would there be if more projects could be scoped in advance and delivered at the optimum time for both client and contractor?

This approach would level out the demand on resource from both sides, allow sufficient time for planning and drive up outputs for Safety, Health, Environmental & Quality. Materials could be procured in advance removing the risk of supplier lead times causing an extended outage for a critical asset.

Recent advances in our ROV technology allows all footage to be provided in full HD quality which ensures that an accurate assessment of the asset condition can be made.

Water quality samples can also be taken at various points within the reservoir using the Dead Spot Sampling™ equipment to investigate if chlorine demand varies within the structure.

Assets found to be of low risk, for example, where little or no sediment buildup is present and the roof integrity is confirmed can be moved back in the programme whereas tanks identified as having the potential for ingress of standing water and/or high levels of sediment can be prioritised.

This strategy would ensure that real value is gained from the investment and would help drive down unnecessary coliform failures without the need for the time consuming and expensive planning works associated with removing key assets from supply.

Read the full article in the Institute of Water Journal here!

For more information, contact the team on 01896 663 330 or email info@pantonmcleod.co.uk

Keep up to date with all our latest news via Twitter. Follow us at Panton McLeod