Drone Inspection

What are the benefits of drone based Inspections?

Reduce field time and inspection costs: Drones can provide access at height faster than many other methods. It is also possible to define repeating inspections where the same images are taken from the same location through automated mission flights. The need for temporary structures to enable access is removed.

Reduced risk: The removal of the need to work at height dramatically reduces the overall risk of the inspection mission.

Faster analysis: The use of AI enables us to quickly identity issues and then manually assess them to ensure that they are a real issue.

Better Records: By definition a drone has a GPS on board with location and heading data - this data is recorded with the captured images. This coupled with the 3D modeling of assets provided an unparalleled level of insight to clients without even going to the site.

Low downtime: Most manual inspections require shutting down equipment to avoid damage or risk of injury to inspection personnel. It is often possible to reduce or eliminate the downtime altogether. In addition the removal of requirement of access structures reduces the overall time of the inspection.

High quality visual data

We are capturing inspection data with cameras up to 48mpx. This enables our clients to get even closer to the asset from the data provided. Images can be captured from a range of positions and these positions recorded to ensure a repeatable future inspection.

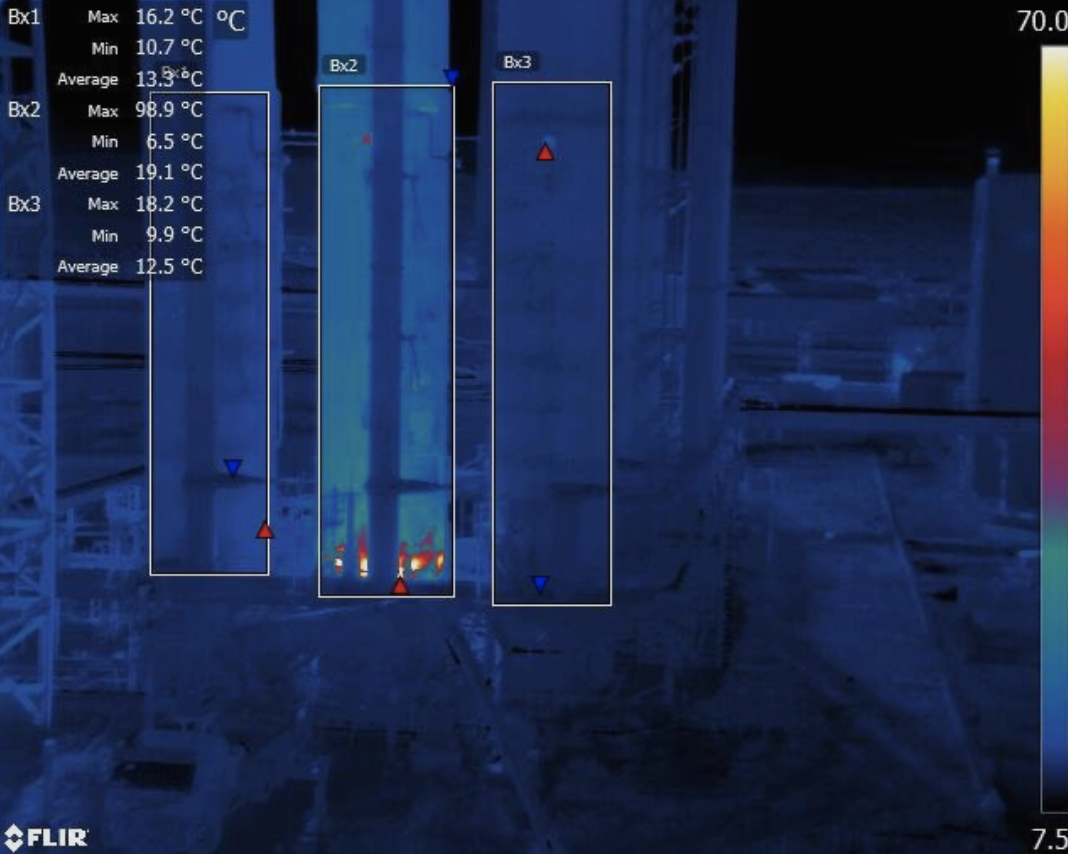

High Quality Thermal Data

We have the capability to capture high resolution radiometric thermal images and thermal video. Radiometric thermal images contain actual thermal data that can be interrogated and analysed off site.

An example of this is in the image to the left.

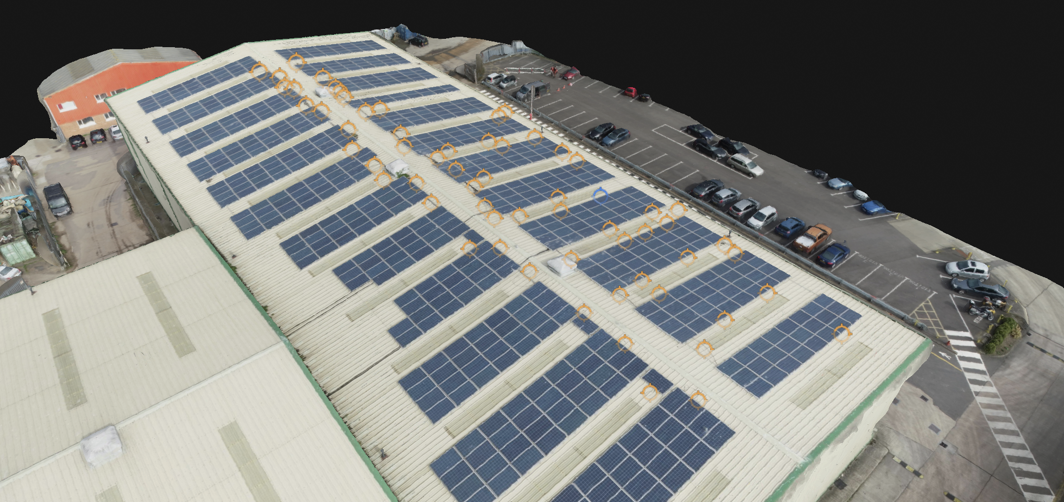

Capture a digital twin to inspect at your desk

Inspecting an asset using a 3D model can be a highly effective way to identify potential issues and assess the overall condition of the asset. With a 3D model, it is possible to view the asset from any angle, identify issues and even accurately measure them.

By leveraging 3D modeling technology, asset owners can improve their ability to manage maintenance and repairs, optimize performance, and ultimately extend the life of their assets.

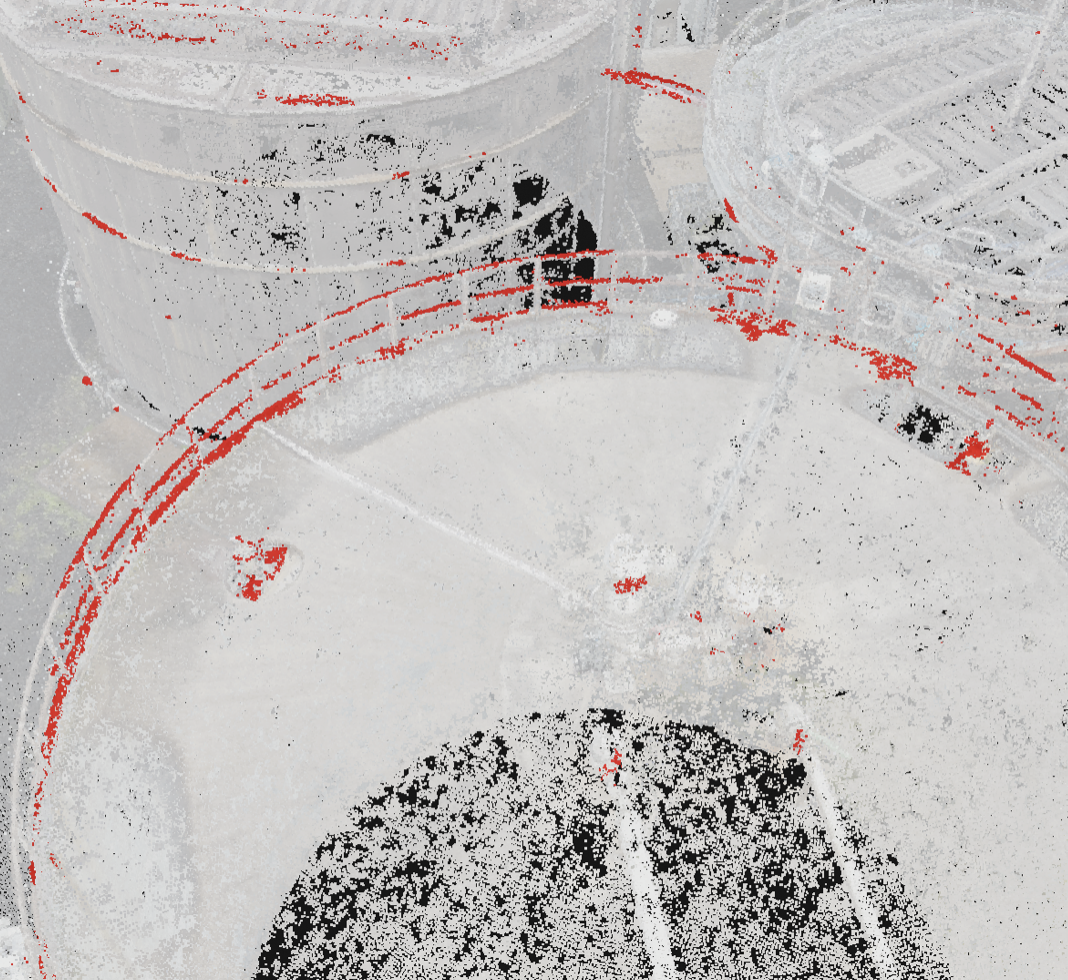

Use AI to complete faster initial assessments

AI can provide support to the inspection process, by leveraging machine learning algorithms, AI can analyze large volumes of data from sensors, images, and other sources to detect many different types issues. In the image to the right the 3D model data from a whole site has been analysed to identify corrosion. This data is validated by an inspector to ensure the overall accuracy of the findings.

Have questions or need assistance?

MAILING LIST SUBSCRIPTION

Join our mailing list for important industry updates and news. We’ll never sell or share your email address, and you can unsubscribe at any time.