How the internet of things can deliver best in class water quality.

We are excited to be working with US industry leaders PAX Water Technologies to help revolutionise the way water quality is managed across distribution networks.

The suite of solutions provided by ourselves and PAX Water Technologies offers the industry the opportunity to make a major step change in terms of improving water quality compliance while also reducing operational costs, energy, and chemical usage.

Using smart monitoring, powerful yet energy efficient mixing, accurate dosing, intelligent THM removal and responsive residual control software the distribution network can manage itself. The combined impact results in reducing customer contacts and preventing water quality failures.

Simon Jefferson explains, “the traditional approach to treatment and distribution considers each as a separate phase, water is produced ‘manufactured’ to the highest standard under closely controlled factory-like conditions before being sent out through distributions assets with the goal of maintaining sufficient quality through to the customer’s taps.”

“To enable the water to make this journey and retain sufficient residual it is often highly chlorinated before it sets off, and although this does safeguard against bacteriological growth it can lead to increased levels of regulated DBPs (disinfection by-products) such as THMs (trihalomethanes).”

“Higher chlorine levels can also create customer contacts for taste and odour, but even with high chlorine, or chloramine residuals the monitoring of the distribution system is often quite rudimental.”

“When things go wrong, water companies are quick to act, but this means the intervention has been too late, even when they do intervene their decision making is based on estimations and misinformation.”

“With increasing competition in the market, ever rising compliance standards, customer expectations and pressure on operating budgets it is time to take a step back and think about the challenge again.”

It all starts with a mixer.

Storage assets such as service reservoirs provide essential resilience to supplies and are as such, a buffer in the distributions system. Although regularly sampled, most reservoirs are designed to store water, and not create sufficient mixing, water often short circuits from the inlet to outlet with the remaining water stagnating in dead zones.

Asset owners can assess the quality of the water before it enters, and as it leaves, but sampling the true condition of the water within the whole asset is not possible. This results in interventions including secondary chlorine boosting being made without sufficient knowledge of the condition of the body of water held within.

The installation of an energy efficient active PAX mixer provides several immediate benefits, these include removal of the dead zones leading to consistent water quality across the whole asset, greater disinfection efficiency, reduced sedimentation, lower levels of biofilm formation and the ability to rely on the outlet sample as a true representation of the stored water quality.

Residual Control

Whether chlorine or chloramine is used as the primary disinfectant, a healthy and well managed residual is essential to protect public health, prevent bacteriological failures and avoid customer contacts.

Failure to efficiently dose the stored water can increase DBPs or lead to raised incidents of nitrification. Traditional methods of residual control involve manual sampling, or automated sampling without the benefits of a well-mixed tank, neither offer an appropriate solution.

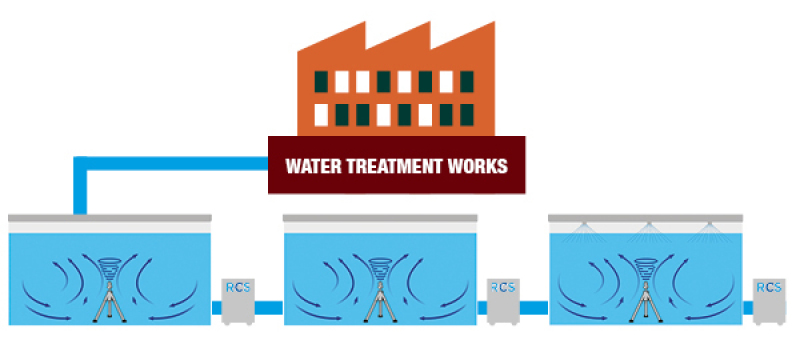

By installing a fully automated Monoclor™ RCS (residual control system) a storage tank can monitor its own residual and intervene to maintain a predetermined level of compliance.

The Monoclor™ RCS achieves this through constantly monitoring the residual within the well-mixed tank. The water quality station and Monoclor™ RCS Smart controller work in conjunction with an automated dosing skid to deliver chlorine or chlorine and ammonia at the point of need, and the active feedback loop ensures free chlorine or monochloramine remain at target levels.

THM Removal

In addition to managing residual levels within the distribution network, it is also possible to extend treatment processes past the fence line of the water treatment works.

The PAX TRS™ (Trihalomethane Removal System) is a chemical free, energy optimised solution to remove THMs through a combination of mixing, aeration and ventilation technology.

Due to the nature of THMs, which form over time through the reaction of natural organics and chlorine, the system can be deployed at specific areas within the distribution system. This targeted investment provides cost savings when compared to alternative solutions which focus on treating 100% of the work’s output.

The PAX TRS™ system also provides guaranteed success against the predetermined process goal.

The network effect

By connecting smart assets through Scada integration, a smart network can be created and controlled from a central point. This holistic approach to network management allows greater control than previously possible. Experienced network operators are still able to provide governance and oversight, monitoring station performance is calibrated and verified, and the elimination of manual interventions removes the risk of human error.

Water quality is protected and maintained across the whole storage network whether that be large strategic reservoirs early in the system, or smaller local storage points at the furthest point from the treatment works where water age can traditionally affect water quality performance.

Monoclor™ RCS systems provide stable disinfectant residuals and prevent the risk of nitrification, and where required, PAX TRS™ systems manage THM levels and improve the resilience of supply by allowing retention times to be increased.

Best in class water quality

A step change in improving water quality performance without significantly increasing operational cost can only be achieved by considering the challenge in a new way “smart distributed treatment” provides that solution.

Networks of smart assets provide an energy efficient means of protecting and improving water quality from treatment to tap. Intelligent active feedback controls remove the need to deploy operational staff, and efficient disinfection prevents compliance failures and customer contacts.

For more information, contact the team on 01896 663 330 or email info@pantonmcleod.co.uk

Keep up to date with all our latest news via Twitter. Follow us at Panton McLeod