Maintaining disinfectant residual levels in drinking water distribution systems is a challenge. Water must travel through miles of pipes and is often stored in service reservoirs and other treated water storage points for several days before reaching customers.

Long contact times to both the distribution network and water storage assets can cause the deterioration of water quality which increases the risk of bacti failures and results in unnecessary expense for water providers as they attempt to manage the problem.

The installation of an energy efficient mixer can provide a range of chemical-free benefits that can mitigate these risks and improves water quality performance. To understand the solution, it is interesting to consider what is causing the issue.

The Problem

After travelling through miles of pipework fresh residual rich water enters the storage asset and the velocity of the water drops.

Some of this new water then finds the easiest path towards the outlet pipework “short-circuiting” which in turn prevents the remaining older water from entering supply. In addition, these areas of lower residual “dead spots” create a chlorine demand on freshwater entering the tank and can lead to the formation of disinfection by-products.

This cycle can continue with water ageing in the dead spots for extended periods. Depending on the layout of the asset and local conditions two different type of separation are common: These can be thermal, or chemical stratification. Once established both are very difficult to correct without draining and emptying the tank completely.

Whereas the driver for each type of separation is different, the results are similar. While one body of water retains disinfectant and passes through the asset the other loses residual disinfectant and becomes a water quality risk allowing bacteria to establish.

We have seen this deterioration in water quality in many projects where our ROVs (remotely operated vehicles) have been used to take samples from isolated, low-velocity areas in water storage tanks.

When demand exceeds the incoming supply and the water level in the asset drops, some of the aged water will enter supply, the symptoms are often a rapid decline in disinfectant at the outlet sample point, and the increased risk of bacteriological failure out in the distribution supply network.

The Solution

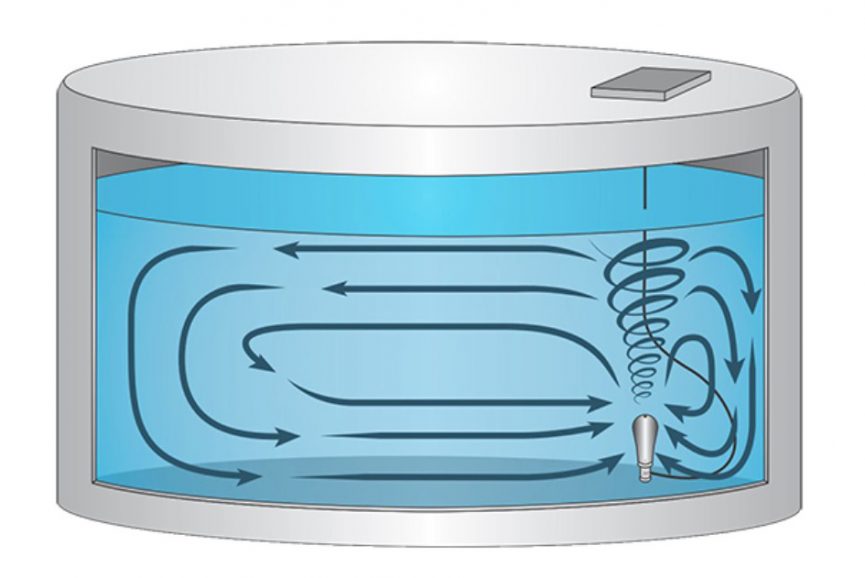

If water quality across an asset can be kept consistent through powerful mixing inside the tank, then a number of key benefits can be found.

Firstly, as mixing removes dead spots the whole water body is exposed to fresh water containing disinfectant. As water quality across the asset is then more consistent it requires less overall chlorine, saving cost, optimising chemical use and reducing the formation of disinfection by-products. The water quality risk associated with aged water is also removed.

Secondly, as the water body is well-mixed asset owners have confidence that the outlet samples are providing a representative record of the water being supplied to the distribution supply network. This allows any interventions to be planned with confidence with accurate timely and consistent water quality data.

In addition to these primary benefits, there are other indirect effects and cost savings. This includes a reduced level of sediment deposition as water is kept in constant motion. As the presence of sediment is known to closely relate to bacteriological risk, reduced sedimentation will reduce bacteriological risk.

Also, biofilm growth on the walls of the tanks will reduce because biofilm tends to grow on surfaces in areas of low disinfectant residual and where water is static. A continuous supply of motive disinfected water will, therefore, prevent growth.

With a reduction in both biofilm growth and sedimentation interventions such as cleaning, frequencies can also be extended, saving money without compromising water quality.

Working in partnership with PAX Water Technologies, our teams can supply a range of powerful energy efficient potable water mixers. Easily installed during planned maintenance, or installed live using robotic equipment the addition of a mixer can change the way operators view their storage assets.

To find out more about how the installation of a mixer could improve water quality across your network contact the team on 01896 663 330 or email info@pantonmcleod.co.uk

Keep up to date with all our latest news via Twitter. Follow us at Panton McLeod